As the owner of a fishery, I was happy when I finally invested in a flake ice machine for my business. But, as time passed, I noticed that the seafood preserved by ice from my machine wasn’t as fresh as it used to be. It had a strange odor, and the taste was off. I knew something was wrong, and that’s when I realized I had neglected to clean my flake ice machine.

Cleaning a flake ice machine may not seem like a big deal. But neglecting this task can affect your customers and business. A dirty ice machine can lead to health hazards and decreased ice quality hence low revenues. The cleaning process may seem daunting, but it can be a straightforward task with the right tools and guidance.

In this guide, you’ll learn how to clean your flake ice machine. This includes disassembling and sanitizing the machine. Additionally, I’ll provide maintenance tips to ensure your machine stays in good condition.

Understanding Flake Ice Machine Cleaning

Cleaning a flake ice machine is an essential task that you need to do. It helps maintain its optimal performance and extend its lifespan.

A flake ice machine produces small, soft flakes of ice. This ice clumps together, leading to clogs, bacterial growth, and other problems. It, in turn, can affect ice quality and machine efficiency. Regular cleaning ensures you can prevent these issues. It also ensures the machine remains in good working condition.

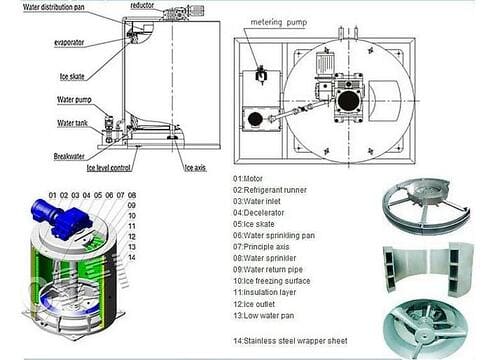

Basic Components of a Flake Ice Maker

Flake ice machines produce soft, small pieces of ice. Flake ice is often used in various commercial and industrial applications. These applications include food storage and processing, medical facilities, and fishing boats. These machines have several essential components that produce and store ice.

- Evaporator: The evaporator is the component responsible for creating the ice. It consists of a cylinder or drum that rotates and is often cooled by the refrigerant. This causes the water to freeze on its surface. The ice flakes into small pieces and drops into the ice storage bin below.

- Condenser: The condenser handles the release of the heat generated during ice-making. It uses a fan to blow air over a series of coils filled with refrigerant. This cools the hot refrigerant and releases heat into the surrounding air.

- Compressor: The compressor is the component that circulates the refrigerant through the system. It compresses the refrigerant gas. This raises its temperature and pressure. Then pumps it through the condenser and evaporator.

- Water system: The water system supplies water to the evaporator. It consists of a water inlet valve regulating water flow into the machine. It also has a pump pumping the water over the evaporator surface.

- Electrical system: The electrical system controls the operation of the machine. It includes components such as the motor, thermostat, and control panel. These components work together to ensure the machine operates well. They ensure the machine produces consistent, high-quality ice.

- Control panel: The control panel is an interface that allows you to operate and check the machine. It includes switches, gauges, and lights that show the machine’s status. It lets users control various functions like ice production rate and temperature.

Why Clean Your Flake Ice Machine?

There are several reasons why cleaning a flake ice machine is necessary.

- Health and Safety Concerns: A dirty flake ice machine can lead to bacterial growth. This can contaminate the ice and pose health risks to consumers. Regular cleaning and sanitizing of the machine prevent the growth of bacteria.

- Maintenance: Regular cleaning and maintenance of the ice maker helps extend its lifespan. It also reduces and prevents costly repairs. The buildup of mineral deposits and other debris in the machine can cause it to malfunction. It can also stop working altogether, resulting in lost profits and inconvenience.

- Energy Efficiency: A dirty flake ice maker can also be less energy efficient. This may lead to higher utility bills. Buildup on the evaporator, condenser, and other parts can cause the machine to work harder. This produces more ice than necessary, increasing energy consumption.

The frequency of cleaning a flake ice machine will depend on several factors. These include the usage level of the machine, water quality, and environmental conditions. Cleaning the machine at least once every six months is often recommended.

But frequent cleaning is necessary if you use the machine many times. Also, more cleaning may be necessary if you use the machine in an area with high mineral content in the water.

Tools and Materials Needed When Cleaning a Commercial Ice Machine

Before we start, let’s review the tools and materials you’ll need to clean your ice machine. You’ll need various tools and materials to make the process effective. Here are some of the tools and materials you should always have before cleaning;

- Soft-bristled brush: A soft-bristled brush is essential for cleaning the machine’s components. This includes cleaning the evaporator and surrounding areas without damaging them. The brush should be gentle enough not to scratch surfaces but firm enough to remove debris or dirt.

- Spray bottle with water and mild detergent solution: It is often used to clean surfaces. Using a mild detergent won’t damage the machine’s surfaces. Using an ice machine cleaner that won’t leave any residue behind is also vital. You can mix the solution in a spray bottle for ease of use.

- Plastic scraper: The plastic scraper removes chunks of ice from the machine’s bin. It’s essential to use a plastic scraper rather than a metal one to avoid damaging any components.

- Clean towel: After cleaning the surfaces of the machine, you need a clean towel to dry them off. This helps prevent any water spots or residue from staying behind.

- Food-grade sanitizer solution: Sanitizing the flake ice maker is essential. It ensures no harmful bacteria or pathogens stay behind. A food-grade sanitizer solution is often recommended. This is to avoid contamination of the ice or food that comes into contact with the machine.

- Gloves and eye protection: It’s a good idea to wear gloves and eye protection when cleaning the ice maker. This is to protect your skin and eyes from any chemicals or debris that may be present.

Preparing the Flake Ice Machine for Cleaning

Before you start to clean an ice machine, it’s crucial to prepare it well. Preparing your ice maker for cleaning ensures the cleaning is safe and effective.

Taking the time to prepare your machine can also help you identify any potential issues. It can also help check areas of concern before they become bigger problems.

1. Turn Off the Machine

Start by turning off the power and water supply to the machine. This is to prevent any electrical hazards or water damage. You can usually find the power switch and water supply valve on the machine itself. If unsure, consult the owner’s manual or contact a professional technician.

2. Empty the Machine

Once you’ve turned off the power and water supply, remove any remaining ice or water from the machine. Begin by emptying the ice bin or storage area, and dispose of any ice or water well. You may need a plastic scraper to remove large chunks of ice stuck to the machine. But be careful not to damage any of the components in the process.

3. Check for Any Damage

After you’ve removed all the ice and water, inspecting the machine for signs of damage or wear and tear is a good idea. Look for cracks, dents, or other damage affecting the machine’s performance or safety. If you notice any issues, note them and consider contacting a technician to address them.

4. Remove Any Removable Parts

Many flake ice machines have removable parts that you need to clean. These include the ice bin, evaporator, water distribution system, and other removable parts. Refer to the manufacturer’s instructions to identify and remove these parts.

5. Soak Removable Parts

Fill a bucket or a can with warm water and a mild detergent solution. Then place the removable parts in the bucket to soak. This helps loosen any dirt or debris and makes them easier to clean later.

6. Gather Cleaning Supplies

Gather all the necessary cleaning supplies. This includes a soft-bristled brush, a spray bottle with water and detergent, and a towel. Also, a food-grade sanitizer.

The Ultimate Guide to Clean Your Flake Ice Machine: Step By Step

Now that you’ve prepared your flake ice machine for cleaning, it’s time to get down to business!

Cleaning your flake ice machine is essential to maintain its optimal performance. It also ensures that the ice it produces is safe and hygienic. Here are the steps for proper ice machine cleaning:

1. Clean the Ice Bin

Using a soft-bristled brush, clean the ice bin to remove any dirt or debris. Pay special attention to the corners and edges of the bin, as these areas tend to collect more dirt and debris.

2. Clean the Evaporator

The evaporator is a key component of the flake ice machine and needs regular cleaning. Use a soft-bristled brush to clean the evaporator. This removes dirt, debris, or mineral deposits. If there are any stubborn deposits, you can use a plastic scraper to remove them.

3. Clean the Water Distribution System

The water distribution system is another important component of the flake ice machine. It needs regular cleaning to ensure it distributes quality water. Use a soft-bristled brush to clean the system, removing any dirt or debris.

Sanitizing the Flake Ice Machine

Sanitizing your flake ice maker is a critical step in cleaning. It ensures no harmful bacteria or pathogens could contaminate the ice or food. Here are the steps to sanitize your flake ice machine:

1. Mix the Sanitizer Solution

First, ensure the machine is dry before applying the sanitizer solution. Then, mix the sanitizer and water according to the recommended dilution ratio. Be sure to follow the instructions. Using too little sanitizer won’t be effective. Yet, using too much could leave a harmful residue on your machine.

It’s important to use a food-grade sanitizer to avoid any potential contamination. Ice or food may come into contact with the machine.

2. Apply the Sanitizer Solution

Once the sanitizer solution is well mixed, spray it over all the machine surfaces. This includes the evaporator, bin, and surrounding ice machine areas. Use a spray bottle to apply the sanitizer solution to all surfaces of the flake ice machine.

Make sure to cover all the nooks and crannies to ensure that all surfaces are well-sanitized. Allow the solution to sit for the recommended time. This can vary depending on the manufacturer and product used. It ranges from a few minutes to half an hour.

Be sure to follow the manufacturer’s manual for the recommended contact time.

3. Rinse the Machine

After the recommended contact time has elapsed, rinse the machine with clean water. Remember to remove any remaining sanitizer solution.

Use a clean towel to remove excess sanitizer solution from the machine’s surfaces. Removing residual sanitizer is essential. It can be harmful if ingested or come into contact with food or beverages.

4. Dry the Machine

Use a clean towel to dry the machine. This will help prevent any water spots or residue.

Reassemble the Machine

After cleaning and sanitizing cycles, reassemble all the parts. Always ensure the components are in place. Here are some things you should consider;

- Reattach the parts: Follow the manufacturer’s instructions to reattach all the removed parts. This includes the ice bin, evaporator, water distribution system, or other removable parts.

- Secure the parts: Once reattached, ensure they are in place. Check that all screws and bolts are well-tightened and that there are no loose or wobbly parts.

- Turn on the machine: Once you reassemble and all parts are in place, turn it on and wait for it to produce ice.

- Check for leaks or issues: As the machine starts producing ice, check for any leaks or issues. Make sure that the ice is being produced at the correct rate and that the machine is functioning well.

Signs that Your Flake Ice Machine Needs Cleaning

A flake ice machine is a valuable appliance for many commercial establishments. It provides a continuous supply of ice for various purposes.

But, if not well maintained, an ice maker becomes a breeding ground for bacteria. This can lead to health hazards and affect the ice quality produced.

So, checking for signs that your flake ice machine needs cleaning is essential. Here are the most common signs:

1. Reduced Ice Production

A decrease in ice production is one of the most evident signs that your flake ice machine needs cleaning. Suppose you notice that the machine is producing less ice than usual. The components are likely clogged with mineral deposits or other debris. This hinders the ice-making process.

2. Dirty or Discolored Ice

Another clear sign that your flake ice machine needs cleaning is the discolored ice. Suppose the ice produced by the machine is cloudy or has a yellowish tint. In that case, it could be because of the mineral deposits or other contaminants.

3. Unusual Odors

If you notice an unusual odor coming from your flake ice machine, it could be a sign that it needs cleaning. The buildup of bacteria and other microorganisms can cause foul smells. This can send it to the ice produced.

4. Unusual Noises

Any unusual noises from your flake ice machine can show a need for cleaning. It could be due to the accumulation of debris or mineral deposits. This can cause the machine to malfunction.

5. Slow Ice Harvesting

If you notice that the ice harvest ice machine is at the expected rate, it could be a sign that it needs cleaning. The ice could be sticking to the components due to the accumulation of mineral deposits. This helps slow the harvesting process.

6. Poor Ice Quality

Sometimes the ice produced by the machine is not in the expected shape or size. It indicates that the machine needs cleaning. The buildup of mineral deposits and other debris can affect the shape and size of the ice.

How Often Should You Clean a Flake Ice Maker

To ensure your flake ice maker’s longevity and proper functioning, you need to clean it. The frequency of cleaning varies depending on the usage of the machine and the environment it is in. Here are some guidelines on how often you should clean your flake ice maker:

- Daily cleaning: It is often recommended to clean the ice bin and sanitize the machine daily. This will prevent bacteria buildup and ensure the ice is safe for consumption.

- Weekly cleaning: Every week, the evaporator should be often removed. You should clean well to remove any mineral buildup or debris. The water system and condenser need cleaning to prevent blockages. This helps ensures efficient operation.

- Monthly cleaning: A deep machine cleaning should be often performed every month. This includes cleaning all components and lubricating moving parts. Water filters should also be often replaced every month.

It is vital to remember that the above frequency recommendations are general guidelines. It may vary depending on the usage and environment of the machine. More frequent cleaning may be necessary if the machine is often used or in a filthy environment. Less regular cleaning may suffice if the machine uses less often or in a clean environment.

Regular cleaning of your flake ice maker will ensure the safety of the ice produced. It improves the machine’s efficiency and lifespan. It is crucial to follow the manufacturer’s instructions on cleaning and maintenance. This ensures optimal performance.

Maintenance and Upkeep of Flake Ice Machines

Regular maintenance is vital to keeping your flake ice maker clean and functioning. Here are some maintenance tips to help keep your machine in top condition:

- Replace the water filter: The filter needs replacement to prevent buildup and blockages. This can damage your machine.

- Check refrigerant levels: To ensure your machine functions well, check the refrigerant level.

- Inspect for wear and tear: Inspect your machine for signs of wear and tear. This includes damaged hoses, loose connections, or rust. Address any issues fast to prevent further damage.

- Keep a maintenance log: Keep track of when you do maintenance tasks and what you do in a maintenance log. This helps you identify patterns or issues that arise over time.

- Clean the machine: Regular cleaning is essential to prevent any buildup of dirt or debris. This can affect the machine’s performance and ice quality. Follow the manufacturer’s recommended cleaning schedule and procedures.

- Check the water quality: The water used in the ice maker is critical to its performance and ice quality. Test the water quality and ensure it meets the manufacturer’s recommended specifications. Consider installing a water filtration system if the water quality is poor.

- Check the machine’s performance: Check its performance, like ice production rate and temperature. This ensures it functions well. Any changes in performance could show a problem that needs checking.

- Replace parts as needed: Water filters, pumps, and sensors can wear out over time. This affects the machine’s performance. Inspect these parts and replace them as needed to maintain optimal performance.

- Train staff on proper use: Proper use of the machine is essential to maintain cleanliness. Train staff on the correct procedures for using and cleaning the machine. This includes handling ice and water.

- Keep the machine clean: The ice maker’s environment affects its cleanliness and performance. Keep the machine clean, dry, and well-ventilated to prevent dirt or debris buildup.

You ensure your machine continues functioning by performing these simple tasks. Avoid any costly repairs in the future.

Troubleshooting Common Issues

Flake ice makers are complex equipment that can experience various issues over time. Problems can sometimes arise with your flake ice maker despite your best efforts. Common issues include ice buildup, the machine not producing ice, and strange noises.

If you have any issues with your flake ice maker, there are steps you use to troubleshoot the problem. First, consult the ice machine’s manual or consult a professional technician. They can help diagnose the issue and determine the best course of action.

Here are some problems you may encounter with your flake ice maker and their solutions:

- Poor quality ice: Your flake ice may come out in small, irregular pieces or has impurities. It may be due to a dirty or damaged evaporator. Try cleaning the evaporator according to the manufacturer’s instructions. Check for any damage or wear that may need replacement.

- Machine not producing ice: If your machine isn’t producing ice, it may be due to a bad compressor. It can also be because of a clogged water filter. Check the compressor, ensure it’s functioning well, and replace the water filter.

- A machine producing too much ice: If it has too much ice, it may be due to a faulty ice level sensor or control board. Check these components and replace them if necessary.

- Machine making unusual noises: Your machine may make noises, like grinding or knocking. It may be due to a malfunctioning motor or gear. Check these components and replace them if necessary.

- Ice machine leaking water: Your flake ice maker may sometimes leak water. It may be due to a damaged water line, clogged drain line, or gasket. Check these components and repair or replace them as necessary.

- Machine not turning on: If your flake ice maker isn’t turning on, it may be due to a power issue. The issue may be a blown fuse or tripped circuit breaker. Check these components and replace or reset them as necessary.

If you’re experiencing these issues, address them to avoid damage or safety concerns. Consult the manufacturer’s instructions or a qualified technician for guidance. They will help you troubleshoot and repair your specific flake ice machine model.

Conclusion

Cleaning your flake ice machine is crucial for both commercial and industrial use. A well-maintained ice machine ensures great ice quality and extends the machine’s life. This saves you money on costly repairs or replacements. Following the steps outlined in this guide, you can clean and sanitize your flake ice machine. This keeps it running well and producing high-quality ice for your needs.

Regular maintenance and cleaning of your ice maker are vital in preventing issues. These issues include low ice production, discolored ice, unusual noises, and freezing up. Regular inspections and cleaning allow you to catch and address potential issues. This is before they become costly repairs or replacements. Additionally, proper use and storage of your machine also prevent issues from occurring.