If you’re looking for a new ice machine, one of the most critical components is the evaporator. The evaporator handles freezing the water to create ice. Having the right evaporator can make all the difference in the quality and quantity of ice.

In this article, we’ll provide an in-depth guide on choosing an evaporator for your ice machine. We’ll cover everything from understanding evaporators to considering factors when choosing one. We’ll also look at popular brands, models, and maintenance and care tips.

Understanding Evaporators

Before we dive into how to choose an evaporator for your ice machine, let’s explore the evaporator.

What is an Evaporator?

An evaporator in an ice machine is a component responsible for freezing water to create ice. The evaporator typically consists of a series of tubes or plates. The refrigerant flows through the tubes absorbing heat from the surrounding water and causing it to freeze.

As the ice forms on the evaporator surface, it is eventually scraped off by a mechanical device. It is then collected in a bin for use. The efficiency and effectiveness of the evaporator are critical to the overall performance of the ice maker. They determine the speed and quality of ice production.

Types of Evaporators

Evaporators are an important component of industrial ice machines. They are responsible for extracting heat from the water and turning it into ice. There are several types of evaporators available, each with advantages and disadvantages. The following are the common types of evaporators used in industrial ice machines:

Plate Evaporators

Plate evaporators comprise a series of metal plates. The water flowing between the plates and the refrigerant flowing on the other side. This design maximizes the heat transfer area and is ideal for smaller ice machines. Plate evaporators are generally more affordable than others. But they may need more frequent cleaning.

Shell-and-Tube Evaporators

Shell and tube evaporators consist of a shell filled with refrigerant. It also has a series of tubes carrying the water. The refrigerant absorbs heat from the water, causing it to freeze. This type of evaporator is often used in larger ice machines due to its higher capacity. Shell and tube evaporators need less frequent cleaning than plate evaporators. But they are generally more expensive.

Immersion Evaporators

Immersion evaporators are often submerged in the water. It is then chilled by the refrigerant circulating inside the evaporator. This type of evaporator is often used in small countertop ice machines. It is also used for making specialty ice shapes. Immersion evaporators need regular cleaning to prevent mineral buildup.

Falling Film Evaporators

Falling film evaporators are often designed to handle high volumes of water. They are usually used in ice machines with a capacity of over 10 tons. The water distributes over a series of plates. The refrigerant circulated on the other side, causing the water to freeze. Falling film evaporators need less maintenance than other evaporators. But they are the most expensive.

How to Choose an Evaporator That is Right for Your Ice Machine

Now you have a basic understanding of evaporators. So, let’s dive into the factors to consider when choosing one for your ice machine.

1. Ice Production Requirements

One of the most critical factors to consider is your ice production requirements. The evaporator’s capacity must match the intended application’s ice production needs. How much ice do you need to produce in a day? Do you need a high-capacity machine or a smaller one?

The following are the key considerations when determining the ice production requirements:

- The Volume of Ice Needed: The first consideration is the amount of ice you need to produce. This is often determined by considering the intended use of the ice. For example, a bar or restaurant may need less ice than a fishing vessel or food processing facility.

- Frequency of Ice Production: The frequency of ice production is another important consideration. A high-capacity evaporator may be necessary for applications requiring continuous ice production.

- Ice Type and Size: Different types and sizes of ice need different amounts of time and energy to produce. For example, producing small, flaked ice requires a different type of evaporator. Producing more extensive block ice needs another different type.

- Environmental Factors: The site’s environment can also affect the ice production requirements. For example, higher temperatures or humidity levels may need a larger evaporator capacity. This is to maintain the ice the machine produces.

The evaporator you choose should be able to keep up with your ice production needs. If you select an evaporator that is too small, you may not be able to produce enough ice to meet your needs.

A large evaporator on an ice machine may waste energy and money, producing more ice than you need.

2. Water Quality and Mineral Content

The quality of your water can also play a role in the type of evaporator you choose. This is because of the water quality used in the ice-making process. In turn, it impacts the evaporator’s performance and longevity.

Water with high mineral content causes mineral buildup on the evaporator surface. This can cause reduced ice production and cause it to malfunction over time. This buildup can also lead to increased energy consumption and higher maintenance costs.

Also, water with high mineral content can affect the taste and appearance of the ice produced. This makes it less appealing to customers.

In fact, water with low mineral content can be corrosive to the evaporator. It can also corrode other components of the ice machine. This can also lead to increased maintenance and replacement costs over time.

For longevity and efficiency, use water with a balanced mineral content. Always check and clean the evaporator to prevent mineral buildup.

Hard water high in mineral content can cause mineral buildup on evaporator plates. This reduces their efficiency and lifespan.

If you have hard water, choose an evaporator less prone to mineral buildup. For example, a shell-and-tube evaporator. Or, you may need to invest in a water filtration system. The system removes the minerals from your water before it enters the ice machine.

3. Energy Efficiency

An evaporator’s efficiency affects the ice machine’s energy consumption and operating costs. An energy-efficient evaporator will save you money on your energy bills. It will also help reduce your carbon footprint.

When choosing an evaporator, consider Energy Star-certified models. Or a high SEER (Seasonal Energy Efficiency Ratio) rating. Consider evaporators that use alternative refrigerants, such as R-290 (propane) or R-600a (isobutane). These have lower global warming potential than traditional refrigerants.

Evaporators well designed to transfer heat and cool the water need less energy. For example, a plate evaporator can be more efficient than a shell and tube evaporator. This is due to its increased surface area and improved heat transfer.

4. Material and Coating

The evaporator’s material and coating can impact the ice machine’s efficiency and longevity. The most common evaporator materials are stainless steel, aluminum, and copper. Stainless steel is the most durable and corrosion-resistant material. This makes it a popular choice for industrial ice machines.

Aluminum is lightweight and has good thermal conductivity. But it is less durable than stainless steel and may need more frequent maintenance. Copper is a good heat conductor and corrosion-resistant but is more expensive.

Besides the material, the coating of the evaporator can also impact its performance. Coatings can protect against corrosion and make the evaporator’s surface smoother. This improves ice release and reduces the energy needed for the ice-making process.

Some common evaporator coatings include electroless nickel plating, anodizing, and Teflon coatings. Electroless nickel plating provides a smooth, hard surface resistant to corrosion and abrasion.

Anodizing is a process that creates a protective oxide layer on the surface. This provides good resistance to corrosion and wear. Teflon coatings are non-stick and can improve ice release. But they may not be as durable as other coatings.

5. Design and Configuration

Evaporators are often designed in various configurations, shapes, and sizes. This is to meet specific ice production requirements. Understanding how these designs affect the performance of an evaporator is essential.

An evaporator’s configuration refers to how it is often designed and constructed. There are three most common commercial ice machine evaporator configurations. These are the plate, tube, and shell and tube configurations.

Plate evaporators are the most efficient type. They have a large surface area that facilitates rapid heat exchange. Tube evaporators are usually used for larger industrial ice machines. They are more durable than plate evaporators. Shell and tube evaporators are highly-efficient and suitable for heavy-duty ice production applications.

The design of an evaporator also plays a critical role in its performance. An efficient design maximizes heat transfer and ice production while minimizing energy consumption. Factors like the size and shape of the heat exchange surfaces impact the design. Other factors include the number of refrigerant circuits and the refrigerant flow rate.

6. Cost Considerations

Cost is always a consideration when purchasing equipment, and evaporators are no exception. The cost of an evaporator can vary depending on the type, size, and brand.

It’s also important to consider the long-term costs associated with an evaporator. This includes the maintenance and repair costs over the lifetime of the unit. Some evaporators may need frequent maintenance or be more challenging to repair. This drives up the costs of working with the equipment over time.

Another cost consideration is energy efficiency. Some evaporators are more energy-efficient. They help reduce the operating costs of the industrial ice machine. These evaporators may cost more upfront but can save costs over time.

It’s essential to balance the upfront cost of the evaporator with the long-term costs. The long-term ones are those costs associated with maintenance, repairs, and energy efficiency. This helps ensure that the industrial ice machine remains cost-effective over its lifetime.

Additionally, it’s essential to consider the quality and reliability of the evaporator. A low-cost unit prone to breakdowns or requiring frequent repairs can cost more in the long run.

It may be tempting to go for the cheapest option. But remember that a pricey evaporator may be more energy-efficient and durable. This saves you money in the long run. It’s also vital to consider the cost of maintenance and repairs over the evaporator’s life.

7. Available Space and Installation Requirements

The size and shape of the evaporator can determine how it will fit into the available space. It also determines the installation requirements for the ice machine.

It is vital to measure the available space for the evaporator and choose a size that fits. Some types of evaporators may need more space for installation. Also, consider the shape of the evaporator. Ensure it can fit into the available space without obstructing any other equipment.

You should consider the installation requirements for the evaporator. This includes the type of power required for the evaporator and whether you can get it at the site. You must also consider the location of water and drainage lines. This ensures they are well-installed and connected to the evaporator.

Additionally, consider the accessibility of the evaporator for maintenance and repairs. The evaporator should be easy to access for cleaning, repairing, and replacing parts. This will help ensure the ice machine runs well over time.

Popular Evaporator Brands and Models

Now you know what to consider when choosing an evaporator. Next up, let’s look at some popular brands and models.

1. Manitowoc Ice

Manitowoc Ice is a leading manufacturer of ice machines and evaporators. Their NEO evaporator series uses a patented cleaning system to prevent mineral buildup. This way, it extends the life of the Manitowoc Ice machine evaporator.

They have various evaporator models, including the B-style, C-style, D-style, and V-style evaporators. These evaporators have high-quality materials for easy installation, maintenance, and cleaning.

The B-style and C-style evaporators are popular for their durability. The D-style and V-style evaporators are for achieving the best efficiency and performance.

2. Hoshizaki

Hoshizaki also offers a range of evaporator models. These include the IM and KM series evaporators. These evaporators are usually made from stainless steel. They boast durability, reliability, and ease of maintenance.

The IM series evaporators are for under-counter ice machines and countertop ice makers. But the KM series evaporators are for larger ice machines.

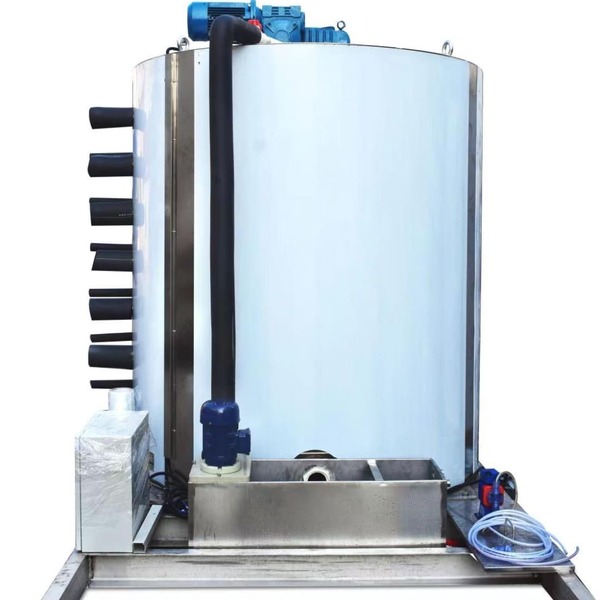

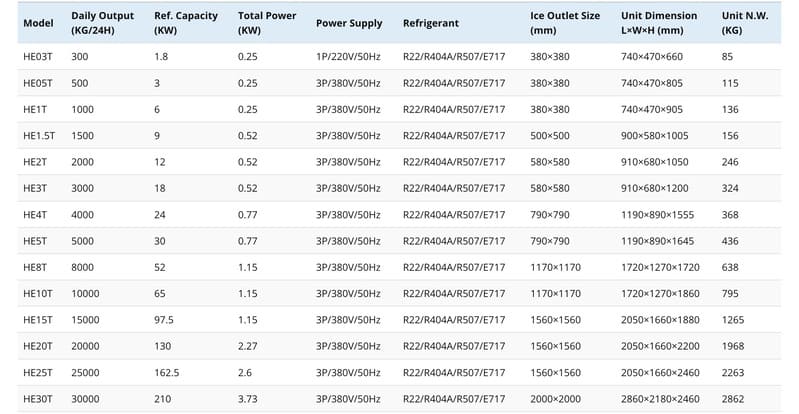

3. Hiceay

Hiceay is a newer brand in the industrial ice machine industry. But it has gained popularity due to its innovative design and high-quality materials. Their Prodigy series of evaporators use a unique design. The design optimizes ice production while reducing energy consumption.

Hiceay offers a range of evaporator models. These evaporators have high-quality stainless steel and boast easy installation, maintenance, and cleaning. Most often than not, they focus on evaporators for larger commercial ice machines.

Here are some of the evaporator models offered by Hiceay.

Maintenance and Care for Evaporators

Proper maintenance and care are essential for keeping your evaporator running. Here are some tips for maintaining your evaporator:

- Clean the evaporator to remove any mineral buildup or debris. Follow the manufacturer’s instructions for cleaning.

- Check the evaporator for any signs of damage or wear and tear. Replace any damaged parts as needed.

- Keep the area around the evaporator clean and free of debris.

- Has a professional inspected and serviced the evaporator at least once a year?

- Consider investing in a water filtration system. The system helps remove minerals and other contaminants from your water.

Conclusion

Choosing the right evaporator for your ice machine is essential. It is efficient and cost-effective in producing high-quality ice. When selecting an evaporator, consider your ice production requirements. You also want to consider water quality, energy efficiency, cost, and installation requirements.

Popular brands offer a range of evaporators with unique features and advantages. These include brands like Hiceay, Manitowoc Ice, Hoshizaki, and Scotsman.

Finally, proper maintenance and care are essential for keeping your evaporator running well. Clean the evaporator and always check for damage. Always have it inspected by a professional at least once a year.

Following these tips, you can choose an evaporator for your ice machine. As a result, you can enjoy high-quality ice for years to come.