A flake ice machine can be a significant financial investment, so it’s important to understand the cost before making a purchase. The cost of a flake ice machine can vary greatly depending on its size, features, and capacity. Small machines may start at $2,000 while larger ones can easily cost up to $20,000 or even higher.

This blog post will explore how much a flake ice machine costs, and the elements that affect the cost of a flake ice machine, providing an in-depth analysis.

We will begin by discussing what a flake ice machine is and its benefits. Then, we’ll delve into different types available in the market and how size, capacity, features, technology, brand, and quality impact their pricing. Furthermore, we’ll cover average costs for both commercial-grade and industrial-grade machines.

Lastly but importantly, we’ll explore financing options such as leasing or loans to help you make your purchase more manageable. Additionally, maintenance costs including regular cleaning procedures and replacement parts will also be discussed to give you a comprehensive understanding of owning a flake ice machine.

By examining all these aspects thoroughly together with answering “How much does a flake ice machine cost?”, you’ll be well-equipped to make an informed decision when investing in this crucial equipment for your business.

Flake Ice Machine Costs and Factors

The prices of flake ice machines can range from $2,000 for smaller units to over $20,000 for larger commercial-grade machines. It’s important to consider the size of the machine when determining your budget as it will directly impact its capacity for producing flake ice flakes or chips.

Evaluating Price Ranges Based on Size and Features

Prices of commercial ice machines can vary greatly, with different manufacturers offering a range of features and costs. Some factors that contribute to these variations include:

- Size: Larger flake ice makers generally have higher production capacities but also come with increased costs.

- Type: There are several types of flake ice machines available such as air-cooled, water-cooled, or remote condenser units which can influence their overall price point.

- Features: Additional functionalities like built-in storage bins or advanced control systems might increase the initial investment required but could provide long-term benefits in terms of operational efficiency.

Importance of Selecting the Right Capacity

Selecting an appropriate capacity for your commercial-grade flake ice maker is crucial not only from a financial standpoint but also because it impacts how well your business meets its cooling needs during peak demand periods.

To determine what size machine to make ice would be best suited for your specific application consider factors, such as daily usage requirements (in pounds), seasonal fluctuations in demand if applicable within your industry sector along with any potential future growth plans being considered moving forward.

For example, a seafood distributor might require a larger capacity flake ice machine compared to a small food processing plant due to the higher volume of products that need cooling. By accurately assessing your needs and comparing them with available options on the market you can make an informed decision when purchasing your flake ice machines.

Flake ice machine costs are largely determined by the size and features of the unit, making it important to select a model with an appropriate capacity for your needs. To ensure you make a sound investment in a quality flake ice machine, we will now explore some of the leading manufacturers and models available in today’s market.

Leading Manufacturers and Models

Several leading manufacturers produce commercial-grade flake ice machines designed specifically for high-volume usage in industries such as fisheries, seafood distribution, chilled meat import/export businesses, food processing plants, etc. Choosing an appropriate model from reputable brands with good customer reviews is essential for ensuring reliable performance.

Top Commercial-Grade Flake Ice Machine Brands

- Hiceay: As a premium quality ice machine manufacturer, Hiceay offers both commercial and industrial flake ice machines and tube ice machines to cater to various industry needs.

- Manitowoc Ice: Manitowoc is known for its diverse range of commercial ice machines including ice cube, nugget ice, and flake options that are suitable for different applications.

- Scotsman Ice Systems: Scotsman has been manufacturing innovative and efficient commercial ice makers since the early 1950s. Their product line includes a variety of flake models to choose from.

- IceMac Global: Specializing in industrial refrigeration equipment production; they offer advanced technology-based solutions like air-cooled or water-cooled systems in their products.

Popular Models Among Various Industries

- HICEAY HF1000: With a daily capacity of up to 2205 lbs (1000 kg) per day this model can handle even the most demanding requirements while maintaining energy efficiency and reliability.

- Manitowoc RFF-1300A: This air-cooled flake ice machine produces up to 1359 lbs (616 kg) of ice per day, making it suitable for medium-sized operations such as seafood distributors or meat processing plants.

- Scotsman FME2404AS-32B: A high-capacity model with a daily production rate of up to 2455 lbs (1113 kg), this unit is perfect for large-scale food processing facilities or fisheries that require consistent and reliable ice supply.

- IceMac FIW500-WC: This water-cooled industrial flake ice maker has a capacity of producing up to 1102 lbs (500 kg) per day. It’s an ideal choice for businesses looking for compact yet efficient machines.

It is essential to investigate various models and their characteristics thoroughly before selecting the right one that fits your needs while offering long-term operation and resilience. Thoroughly researching the various models of commercial-grade flake ice machines available in the market can help you make a knowledgeable selection that fits your needs and offers resilient reliability.

Leading manufacturers and models of flake ice machines offer reliable performance, cost-effective solutions, and the latest technology to meet your business needs. Exploring the capabilities of various flake ice machine models, additional features can be identified to gain a better comprehension of how they operate.

Components and Functionality

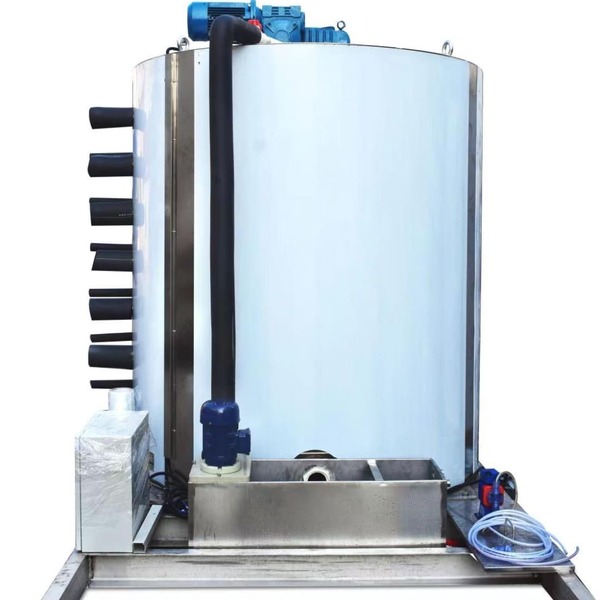

Commercial flake ice makers typically include at least two major components – an evaporator where water freezes into thin layers before being scraped off by rotating blades; and a refrigeration system responsible for maintaining optimal temperatures within the unit during operation. Some models may also feature additional functionalities such as built-in storage bins or advanced control systems allowing users greater flexibility in managing their production process.

Evaporators and Refrigeration Systems Explained

The evaporator is a crucial component of any commercial ice machine, as it’s responsible for turning water into ice flakes. The evaporator consists of a drum with cooling coils that freeze the water on its surface while rotating blades continuously scrape off the formed ice layer to create flake ice.

This process ensures consistent quality and size of produced flakes, making them ideal for various applications like fishery, seafood distribution, chilled meat import/export businesses, food processing plants, etc.

In addition to the evaporator, another essential part of flake ice machines is their refrigeration system. It plays a vital role in maintaining proper temperature levels inside the unit during operation. Most commercial-grade refrigeration systems employ either air-cooled or water-cooled techniques to sustain internal temperatures at the required level for successful freezing processes while avoiding potential damages due to excessive heat buildup.

Additional Functionalities Available in Certain Models

- Built-in Storage Bins: Some high-end flake ice makers come equipped with integrated storage bins explicitly designed for holding large quantities of freshly made ice flakes. For companies that require a steady flow of ice, such as seafood vendors or food production facilities, having an integrated storage bin for the freshly made flake ice can be quite advantageous.

- Advanced Control Systems: Modern flake ice machines may also include sophisticated control systems allowing users to monitor and adjust various aspects of their production process more easily. For example, some models offer touchscreen interfaces with customizable settings like temperature controls, ice thickness adjustments, and even remote monitoring capabilities via smartphone apps or web-based platforms.

In conclusion, understanding the components and functionalities of commercial flake ice machines is crucial when selecting the right model for your business needs. Make sure to consider factors like evaporator type, refrigeration system technology (air-cooled vs water-cooled), and any additional features that could improve efficiency or ease of use in your specific application scenario before making a final decision on which machine best suits your requirements.

Components and functionality are the key factors to consider when choosing a flake ice machine, as they determine its overall performance. When deciding on a flake ice machine, another element to mull over is the air-cooled versus water-cooled technology.

Air-Cooled vs Water-Cooled Technology

When purchasing a new commercial-grade flake ice maker, one key factor to consider is whether it uses air-cooled or water-cooled technology. Air-cooled units generally offer more energy efficiency than water-cooled models, making them an excellent choice for businesses looking to conserve cost. This makes them ideal choices if conserving resources is important within your organization’s operations strategy plan moving forward.

Advantages of Air-Cooled Technology

- Energy Efficiency: Air-cooled commercial ice machines, such as flake ice makers, are typically more energy-efficient compared to water-cooled models. This means they consume less electricity to make ice during operation and can help reduce your overall utility costs.

- Ease of Installation: Unlike water-cooled systems that require access to a constant supply of fresh water for cooling purposes, air-cooled machines only need proper ventilation around the unit. This simplifies installation requirements and reduces the need for additional plumbing connections.

- Sustainability: Since air-cooling technology doesn’t rely on large volumes of fresh water for heat dissipation as its counterpart does; it helps conserve this valuable resource which may be particularly beneficial in areas where freshwater availability might be limited or subject to restrictions during drought conditions etcetera.

Comparing Energy Efficiency Between Cooling Methods

To better understand the differences in energy efficiency between these two types of cooling technologies used by various manufacturers when designing their respective lines of high-quality industrial-grade flake ice-making equipment such as those found at Hiceay’s website (www.hiceay.com), it’s essential to compare their respective energy consumption rates during operation.

Typically, air-cooled machines consume around 10% less power than water-cooled models on average due primarily to reduced requirements for additional pumping systems needed to maintain adequate flow rates through evaporator coils etcetera.

Ultimately, the selection between an air-cooled or water-cooled flake ice machine is contingent on your specific needs and preferences. Factors such as available space, access to a reliable water supply, and local climate conditions should all be taken into account when making this decision.

By carefully weighing these factors against each other alongside considering potential long-term cost savings associated with improved energy efficiency levels offered by certain cooling methods over others; you can make an informed choice that best suits both your operational requirements as well as those related directly to achieving more sustainable business practices overall.

Air-cooled tech provides an affordable choice for many uses, delivering great results and dependability. However, proper maintenance of the machine is essential to ensure optimal operation; this can be achieved by choosing an accessible design that allows easy cleaning and servicing.

Maintenance and Cleaning Requirements

Ensuring easy maintenance access is crucial when selecting suitable machinery, so regular cleaning tasks don’t become overly burdensome over time due to poor design choices or neglecting basic upkeep procedures. This can result in reduced performance levels overall.

Importance of Accessible Designs for Easy Maintenance

Selecting a commercial ice machine with an accessible design is essential for maintaining its efficiency and longevity. A well-designed flake ice maker should have easily removable parts, allowing you to clean them thoroughly without any hassle.

Moreover, the evaporator area and other critical components must be simple to reach during routine maintenance checks. Some flake ice machines even come with self-cleaning features which can save time and effort on your part while ensuring optimal performance.

Impact of Proper Upkeep on Machine Performance

- Durability: Regularly cleaning your flake ice machine helps prevent the buildup of mineral deposits, mold, or bacteria that could damage internal components over time. This not only extends the lifespan of your equipment but also ensures consistent product quality.

- Efficiency: By keeping all moving parts clean and well-lubricated (as per manufacturer guidelines), you’ll minimize friction within the system – ultimately reducing energy consumption rates while maximizing output capabilities.

- Safety: Ensuring cleanliness throughout every aspect related directly impacts worker safety by minimizing potential hazards such as slippery surfaces caused by excess water leakage issues etcetera – always prioritize proper sanitation measures within operational spaces where employees must interact regularly alongside these types of devices.

To maintain peak performance levels in your commercial flake ice machine, it’s essential to follow the manufacturer’s recommended cleaning and maintenance schedule. This may include periodic descaling procedures or replacing worn-out parts such as filters or blades. Don’t forget that investing in a high-quality flake ice machine from a reputable brand can make all the difference when it comes to long-term reliability and ease of upkeep.

Maintaining the ice machine’s performance necessitates regular cleaning and upkeep. Additionally, determining the right size of machine for your specific needs should be taken into consideration when selecting an ice machine.

Determining the Right Size Machine

Deciding the right size of the industrial ice maker for your venture can be a tricky job, but it is necessary to guarantee that you have adequate capacity to meet your cooling needs without spending excessively on an appliance with superfluous production abilities. Consider factors such as daily ice usage and peak demand periods within your operation to help determine the appropriate size.

Assessing Daily Ice Usage Requirements

To accurately assess your daily ice usage requirements, start by calculating how much flake ice is needed for each application in your business. For example, if you operate a seafood distribution center, consider how much flake ice is required for packing and preserving fish during transportation.

Similarly, if you run a food processing plant that uses flake ice in its operations, calculate the amount of flake ice needed per batch or product line.

- Fisheries: Approximately 1 kg of flake ice per kilogram of fish caught or processed.

- Seafood Distribution: Around 0.5 kg of flake ice per kilogram of seafood transported or stored.

- Cold Storage Facilities: About 10% -15% additional weight in flake ice compared to products being stored (e.g., meats).

In addition to these specific applications, also account for any other areas where you might need additional amounts of ice cubes or nugget-style ice.

Factoring in Peak Demand Periods

Another important aspect to consider when determining the right size for your commercial ice machine is factoring in peak demand periods. These are times when your business experiences higher-than-normal ice usage, such as during holidays or special events.

To accommodate for these fluctuations in demand, it’s crucial to choose a flake ice maker with enough capacity to handle increased production needs without compromising efficiency or performance. For instance, if you know that your daily average usage increases by 50% during peak seasons, ensure that the selected machine can comfortably meet this additional requirement while still operating within its optimal range.

By carefully assessing both daily and peak period ice requirements and comparing them against available models from leading manufacturers like Hiceay, you’ll be better equipped to make an informed decision on which commercial-grade flake ice machine best suits your organization’s unique cooling demands.

In conclusion, it is important to carefully assess daily ice usage requirements and peak demand periods when determining the right size machine for your business. Additionally, long-term operational costs and warranty coverage should be evaluated to ensure a successful investment in an industrial flake ice machine.

Long-Term Operational Costs and Warranty Coverage

It’s essential to factor in not only the initial cost of a commercial ice machine but also the long-term expenses related to upkeep and repair when investing. By factoring in these expenses, you can make an informed decision that will ensure your flake ice machine remains a valuable asset for years to come.

Evaluating Long-Term Operational Costs

To accurately assess the ongoing costs of owning a flake ice maker, take into account factors such as energy consumption, maintenance requirements, and potential repair expenses. For example:

- Energy efficiency: Air-cooled machines tend to be more energy-efficient than water-cooled units; therefore, choosing an air-cooled model may result in lower utility bills over time.

- Maintenance needs: Regularly cleaning and servicing your machine is essential for optimal performance. Ensure you have easy access to necessary parts or services when needed.

- Potential repairs: While all machines require occasional repairs or replacement parts, selecting high-quality equipment from reputable manufacturers can minimize downtime due to malfunctions or breakdowns.

The Importance of Strong Warranty Coverage

A comprehensive warranty is another critical factor when purchasing a commercial-grade flake ice maker. A strong warranty demonstrates that the manufacturer stands behind their product quality while providing peace of mind should any issues arise during normal use scenarios.

When comparing different models and brands, look for warranties that offer coverage on both parts and labor for at least one year after purchase – some even provide extended warranties of up to five years.

Before finalizing your decision, research the manufacturer’s reputation for after-sales support and customer service. Reading customer reviews can provide valuable insights into their responsiveness and commitment to resolving any potential issues that may arise.

In summary, considering long-term operational costs and warranty coverage when purchasing a flake ice machine will help ensure you make a wise investment in equipment that serves your business well for years to come. By selecting high-quality machines from reputable manufacturers like Hiceay, you’ll enjoy reliable performance backed by strong after-sales support – making it easier than ever to keep things cool.

Frequently Asked Questions How Much Does a Flake Ice Machine Cost?

How much does an ice dispenser cost?

An ice dispenser typically costs between $1,500 and $5,000 depending on its storage capacity and dispensing method. Some models include additional functionalities such as water dispensers or built-in crushers that may increase the price. Be sure to evaluate your specific needs before making a purchase decision.

How much does an ice machine cost to run?

The operational costs of an ice machine depend on factors like energy efficiency, cooling technology (air-cooled vs water-cooled), and maintenance requirements. On average, running an air-cooled commercial-grade unit might cost around $400-$800 per year in electricity bills alone; however, this figure will vary based on local utility rates and usage patterns.

Conclusion

In conclusion, purchasing a flake ice machine is an important decision that requires research and planning. Factors like size, usage, features sought and upkeep expenditure all affect the overall cost of owning a flake ice machine.

The average price for most commercial models can range from $2-5k but may be higher depending on specific needs. Financing options are available to help with initial costs if needed. With proper care and regular maintenance, your flake ice machine will provide many years of reliable service at an affordable cost – much does a flake ice machine cost?

Discover the perfect flake ice machine for your business needs with Hiceay. Our premium quality machines are sure to meet all of your requirements at an affordable cost.