Ice is crucial for many applications ranging from food preservation to medical purposes. But have you ever wondered how people make ice on a large scale?

The answer is in modern refrigeration technology and compressors’ role in ice makers. Compressors are essential in the ice-making process. So, understanding how they work can shed light on this fascinating technology.

Are you curious to know how a compressor helps make ice? If so, then you’ve come to the right place! In this article, we’ll delve into the world of compressors and how they help make ice.

Understanding Refrigeration Basics

Let’s start by talking about the basics of refrigeration. Refrigeration is making a space cooler by removing heat from it. It’s kind of like what happens when we make ice. We’re using refrigeration to take the heat out of the water and turn it into ice!

When you put water in the freezer, it’s not a simple matter of the water getting colder and turning into ice. For water to freeze, it needs to lose heat energy. This is where the role of temperature and pressure comes into play.

A refrigeration system has three main components: the evaporator, compressor, and condenser. The evaporator absorbs heat from the space that needs cooling, like the water that will turn into ice.

The compressor then compresses the refrigerant gas, increasing its temperature and pressure. From there, the pressurized gas flows to the condenser. It releases heat and converts the gas into a liquid. Finally, the cooled liquid travels back to the evaporator to continue the cooling.

What is a Compressor?

Compressors may seem complex, but understanding their basic principles can be simple. Think of a compressor as a device that compresses air or gas, like how you might compress a spring.

By doing so, it increases the pressure of the air or gas, which in turn reduces its volume. This reduction in volume creates a high-pressure, high-temperature environment. The environment is helpful in various applications, including refrigeration and air conditioning.

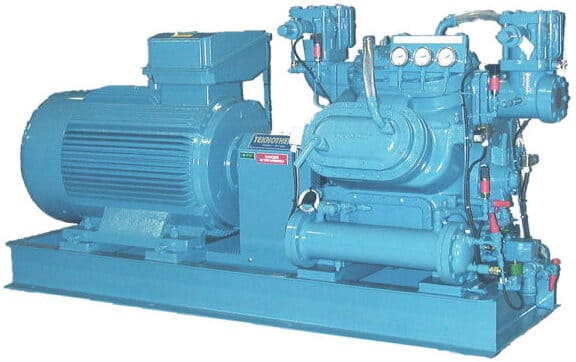

Compressors can come in many shapes and sizes, from small portable to large units. Some compressors use a piston that moves back and forth to compress the air. Others use a rotating mechanism. Despite the different designs, all compressors have similar principles of compression and pressure.

In everyday life, you might encounter compressors in various settings. For example, an air compressor is usually used for powering tools and inflating tires. Or compressors for refrigerators and air conditioners for cooling and maintaining temperature.

Parts of a Compressor and Parts that Helps it Work

Compressors consist of several vital components that work together to circulate refrigerant gases. Here are some parts you might find in a typical compressor or around it:

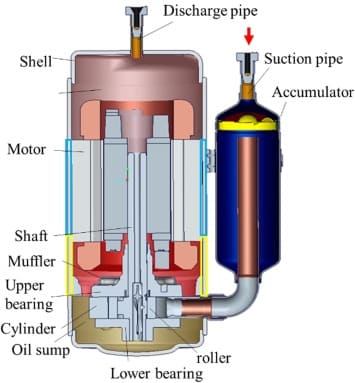

- Motor: This is the power source for the compressor. It provides the energy needed to drive the compressor.

- Compressor pump: This is the heart of the compressor. It consists of a piston, cylinder, and valves. The piston usually moves up and down within the cylinder. This way, it compresses the refrigerant gas and pushes it through the valves.

- Condenser: This is where the hot refrigerant gas cools and condenses into a liquid. The condenser is usually a tubing coil that cools warm air or water.

- Evaporator: This is part of the compressor where the liquid refrigerant evaporates. The liquid absorbs heat from the surrounding environment, causing the temperature to drop. In ice-making machines, the evaporator is where the water freezing takes place.

- Expansion valve: This component regulates the flow of refrigerant gas into the evaporator. It reduces the pressure and temperature of the gas before it enters the evaporator.

- Oil separator: Removes oil from the refrigerant gas before it enters the compressor. This is important because oil can damage the compressor and reduce its efficiency.

- Control panel: This component allows operators to check and control the compressor’s performance. It includes gauges, switches, and indicators. These parts provide information on the compressor’s pressure, temperature, and operating status.

- Compressor housing: This is the outer shell that contains the compressor’s internal components.

- Compressor head: This is the top part of the compressor housing. It contains the intake and discharge ports and the valve plates.

- Valve plates: These are thin, circular discs with ports. They control the flow of refrigerant gases into and out of the compressor.

- Piston or scroll: These are the main compression components. They are responsible for compressing the refrigerant gases and circulating them.

- Connecting rods: These link the piston or scroll to the motor shaft. They allow the compressor to convert rotational energy into linear motion.

- Bearings: These support the rotating components of the compressor and help reduce friction.

- Crankshaft: This is the main shaft that connects the motor to the internal components.

Types of Compressors Used in Ice Making

When it comes to ice-making, compressors play a crucial role in the process. There are different compressors in ice-making, including reciprocating, rotary, centrifugal, and scroll compressors. Let’s take a closer look at each compressor.

1. Reciprocating Compressors

Reciprocating compressors are popular in smaller ice machines, refrigerators, and air conditioning units. They use a piston to compress the refrigerant gas. It then circulates the cooled liquid through the system. They’re reliable and efficient, making them popular for smaller applications.

2. Rotary Compressors

Rotary compressors are better suited for larger ice machines. They use rotating blades to compress the refrigerant gas. This creates a more continuous flow of refrigerant. This makes them more efficient than reciprocating compressors for larger systems.

They’re also known for their durability and low maintenance requirements. This makes them a popular choice for commercial and industrial ice machines.

3. Centrifugal Compressors

Centrifugal compressors use a spinning impeller to compress the refrigerant gas. It creates a high-velocity gas flow. This type of compressor is often used in large industrial ice machines. This is due to its high capacity and efficiency.

Centrifugal compressors are often used in conjunction with other compressors. For example, a centrifugal compressor provides the initial compression of the refrigerant gas. This gas is further compressed by a reciprocating or screw compressor.

4. Scroll Compressors

Finally, scroll compressors are popular for their quiet operation and energy efficiency. They use two spiral-shaped scrolls to compress the refrigerant gas. They create a steady and continuous flow of refrigerant.

This makes them ideal for environments where noise is a concern. They’re also popular for commercial ice makers that need to run always.

When deciding which compressor to use, consider the ice machine’s size and application. Reciprocating compressors are best for small to medium-sized applications. But rotary compressors are better suited for larger systems.

Scroll compressors are ideal for environments where noise is a concern. They are also great for applications where energy efficiency is essential.

How a Compressor Helps Make Ice- The Role of Compressors in Ice-Making

Now that we’ve covered the basics let’s focus on the role of compressors in the ice-making process. The compressor is the heart of any refrigeration system. Its job is to compress the refrigerant gas and increase its temperature and pressure.

Here are the steps on how a compressor helps make ice:

Step 1: The compressor pumps refrigerant gas into the evaporator coil. The refrigerant gas absorbs heat from the water.

Step 2: As the gas absorbs heat, it becomes a high-pressure, high-temperature gas. It is then sent to the compressor.

Step 3: The compressor compresses the gas, causing it to become even hotter.

Step 4: The hot gas flows through a condenser coil, releasing heat into the surrounding air or water.

Step 5: The refrigerant gas turns into a liquid as it cools. It then flows back to the evaporator coil, starting the cycle again.

Through this continuous cycle, the compressor helps cool down the water and turn it into ice.

Factors Affecting the Functionality of Compressors

Compressors are essential components in many industrial and household appliances. These appliances may include refrigerators, air conditioners, freezers, and ice-making machines. Like any other machinery, compressors have various factors that affect their functionality.

1. Size

The compressor size in an ice machine affects the ice production capacity. The larger the compressor, the more ice the machine can produce.

2. Type and Quality of Refrigerant

The type and quality of the refrigerant in the compressor impact its functionality. Using the wrong type or poor-quality refrigerant causes damage to the internal parts. This leads to reduced efficiency or complete failure.

3. Ambient Temperature

Compressors operating in very high or low p may experience reduced efficiency. Extreme temperatures can affect the pressure and viscosity of the refrigerant fluid. This, in turn, affects the compressor’s ability to compress and circulate the refrigerant.

4. Level of Care and Maintenance

Maintaining and caring for compressors in ice-making machines is vital for optimal performance. Regular cleaning and inspections prevent issues such as leaks. Such issues can result in decreased efficiency and higher energy costs.

The demand for advanced and efficient compressors will only increase as industries evolve. So, industries must stay up-to-date with the latest trends in compressor technology. Doing so can maximize their productivity while minimizing their environmental impact.

Maintaining and Troubleshooting Compressors

Regular maintenance and troubleshooting are essential to keep compressors running at their best. Low refrigerant levels, leaks, and compressor failure can arise if care is not done well.

As someone who used to work at a restaurant that relied on ice, I understand how compressors work. I know firsthand the importance of maintaining compressors.

1. Cleaning

One key maintenance aspect is keeping the condenser and evaporator coils clean. This helps ensure the optimal performance of the machine. These coils can become dirty and clogged over time. As a result, it reduces the compressor’s efficiency and ability to transfer heat. To clean the coils, use a soft brush or vacuum to remove dirt or debris.

2. Check and Replace the Refrigerant

Low refrigerant levels cause overworking of the compressor. This can lead to the failure of your machine. It’s important to have a professional technician handle the refrigerant replacement process. It ensures proper handling and disposal.

3. Compressor Inspections

Having a regular maintenance schedule for your ice-making machine is a good idea. This includes compressor inspections. Doing this can help catch any potential issues and prevent major problems.

4. Consult a Professional

If any issues arise, consult a professional technician to diagnose and fix the issue. It’s important to refrain from attempting repairs or maintenance alone. This can be dangerous and cause further damage to the compressor.

Remember, proper maintenance and troubleshooting can help extend the life of compressors. Ensure they are working to ensure better productivity and cost savings.

Energy Efficiency and Sustainability of a Compressor

In today’s world, energy efficiency and sustainability are crucial considerations for any appliance. This means that ice machines and ice makers are no exception. Here are some ways you can make compressors more energy efficient and sustainable.

Using Energy-Efficient Compressors

An energy-efficient compressor can help reduce energy consumption and save money. But it also helps to reduce carbon emissions and promote sustainability.

For instance, compressors are vital for refrigeration in the food and beverage industry. This accounts for a significant part of the industry’s energy consumption. By using energy-efficient compressors, these companies can reduce their energy consumption. They can save on operating costs and lower their environmental impact.

Moreover, compressors are also used in other industries like construction, fishing, and manufacturing. By using energy-efficient compressors, these industries can reduce their energy consumption.

Proper maintenance and care are essential for compressors’ sustainability and energy efficiency. Regular cleaning, proper lubrication, and timely repairs can help improve efficiency.

Using Natural Refrigerants

A great way to reduce the impact of ice makers is by using natural refrigerants. Natural refrigerants, like propane or CO2, have lower global warming potential. This means they have less environmental impact and reduce greenhouse gas emissions.

With energy-efficient compressors and natural refrigerants, ice makers have become more sustainable. This is not only good for the planet, but it can also help businesses save money in the long run.

New Trends and Developments in Compressor Technology

Compressor technology is evolving, with efficiency, durability, and noise reduction advancements.

First, we have variable-speed compressors. These can adjust the cooling capacity based on demand. This can lead to energy savings and a longer lifespan. That means you can have a more efficient ice machine that lasts longer.

Another advancement is the use of digital compressors. With temperature control and lower energy consumption, digital compressors can save money. They also ensure your ice machine works well.

It’s great to see these new technologies emerging. These technologies help make ice machines even more efficient and sustainable. Remember to stay up-to-date with the latest trends and developments in compressor technology. This ensures your machine operates at its best and reduces the environmental impact.

Conclusion

In ice-making, compressors are the backbone of the entire process. They play a critical role in compressing refrigerant gas. This, in turn, generates the necessary cooling effect to create ice. Ice machines are becoming more efficient and sustainable with the new compressor technologies.

Understanding the role of compressors in making ice is essential. The science behind the conversion of water into ice and the use of compressors are crucial.

Proper care of compressors is also vital for improved lifespan and optimal performance. With the appropriate knowledge and attention, compressors help ice-making machines produce consistent ice. It allows for meeting the needs of various industries that rely on ice daily.