Have you ever wondered how tube ice machines work? Today, we’ll dive into a beginner’s guide to tube ice machines. It will help you get a better understanding of how they operate. As you may know, tube ice makers are common in restaurants, fisheries, and storage areas. They help provide a steady supply of ice.

The concept of tube ice makers is pretty simple. They produce ice by running water over a refrigerated surface. The surface causes the water to freeze in long, thin tubes. These ice tubes are then cut into small pieces using a cutter, producing the ice that we all know and love. But how does this process happen?

Well, let’s find out! This guide will explore how tube ice machines work, from refrigeration to ice-making. We’ll also discuss the different types of tube ice makers and what to look for when purchasing one. So, prepare to learn everything you need about tube ice machines!

What is a Tube Ice Machine?

A tube ice machine is a device that produces cylindrical or tube-shaped ice cubes. It makes a large amount of ice. The ice tubes are perfect for cooling fish and seafood in storage. They also keep the products fresh for a longer time.

The machine uses refrigeration to freeze water. It then shapes the ice into tubes using a cylindrical mold. They are crucial for commercial settings because they can produce a lot of ice.

Tube ice machines are popular because they can produce a lot of ice in a short amount of time. Their ice is cylindrical, hence the name “tube” ice. This type of ice is perfect for drinks because it melts little by little and won’t dilute your drink fast.

What is a Tube Ice?

So, you know how ice is usually in cube form, right? Tube ice is like that, except in the shape of long, cylindrical tubes. Think of it like a straw but made of ice.

Tube ice is a type of ice that’s cylindrical in shape. The cool thing about tube ice is that it’s crystal clear and has no impurities. This makes it perfect for cooling beverages or displaying food items. It also melts little by little, so it dilutes your drinks slower than regular ice.

When making tube ice, you pump water into long, cylindrical molds frozen inside out. Once the ice is solid, the molds heat up to release the tubes of ice, which are then cut into smaller pieces for use.

Types of Tube Ice Machines

There are two different types of tube ice machines: air-cooled and water-cooled.

Air-Cooled Tube Ice Machines

Air-cooled tube machines use the surrounding air to cool the refrigeration system. This is unlike water-cooled machines that need a constant supply of water. You can use air-cooled machines in areas with limited water supply or high water costs.

These machines have tubes that freeze water in a tube shape. The machine then cut the ice into small cylindrical shapes. The ice is then collected and stored in a bin until needed. They are popular in restaurants, bars, and other commercial settings. This is because they are efficient and produce a high volume of ice.

But they can be noisy and need a well-ventilated area to operate well. Additionally, they may not be as energy-efficient as other ice makers. They may also need more maintenance to keep them running well.

Air-cooled machines are great if you’re looking for an efficient way to make many ice tubes.

Water-Cooled Tube Ice Machines

Water-cooled and air-cooled machines are not very different. The main difference between them is how they reduce excess heat. Water-cooled machines use water to cool down the refrigerant, unlike air-cooled machines.

They work by circulating water over the evaporator tubes. The process removes heat from the refrigerant and causes the water to freeze and form ice. These machines are crucial for industries that need a large amount of ice. Such industries may include food processing plants, supermarkets, and fishing boats.

Water-cooled machines tend to be more efficient and produce higher-quality ice. Yet, they also need more water and can be more expensive. They’re a great choice if you can access plenty of water and want the best possible ice.

But, they need a constant water supply and may face water quality issues. Additionally, their installation and maintenance can be more complex and expensive.

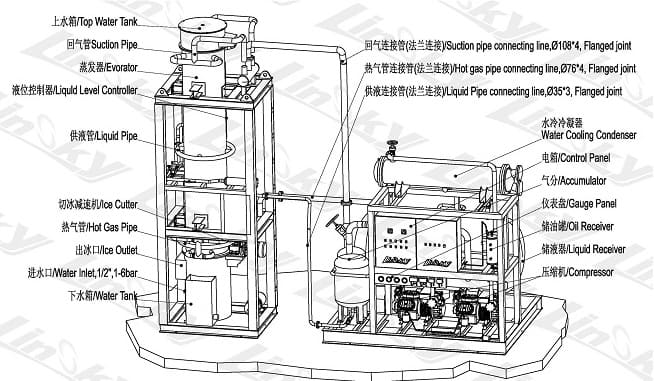

Components of a Tube Ice Maker

A tube ice maker has a few main parts, like the compressor, evaporator, water pump, and condenser.

Evaporator

It’s where the freezing of water into ice tubes takes place. The evaporator is a hollow tube made of metal or plastic, and the refrigerant surrounds it. When the water flows through the tube or water line, the refrigerant absorbs the heat from the water. This makes the water freeze into ice.

Here’s how it works. When refrigerant circulates the tube, it sucks out the heat from the water, causing it to freeze and form ice. It’s like magic! Some of the refrigerants evaporate in the evaporator and form vapor. The vapor enters an accumulator, which functions as a heat exchanger.

Think of it like this: When you put a soda can in the freezer, it gets cold and turns into a block of ice? The evaporator in a tube ice maker does the same thing but on a larger scale. It’svitalt because you wouldn’t be able to make ice cubes without them.

In a nutshell, the evaporator turns water into ice in a tube ice maker. Without it, we couldn’t enjoy those refreshing ice tubes.

Compressor

One of the crucial components of a tube ice maker is the compressor. It’s the part that pumps refrigerant gas into the condenser to help turn water into ice.

Think of it like a bicycle pump – when you pump up a bike tire, the air gets compressed and becomes more pressurized. Well, a compressor works the same way. It takes the refrigerant gas and compresses it, which causes it to heat up. This hot, compressed gas is then sent to the condenser, releasing the heat and becoming a liquid.

Without the compressor, the machine wouldn’t be able to make ice. It’s the heart of the whole process.

Water Pump

Its job is to circulate water from the reservoir to the evaporator, where ice forms. Without the water pump, the water wouldn’t be able to flow into the evaporator, and there would be no ice tubes.

Imagine it like this: Have you ever used a garden hose to water your plants? The water pump in a tube ice machine works like the pressure from the hose. It forces the water through the system to freeze into ice.

The water pump in a tube ice maker is usually powered by electricity. But you can also operate it in a manual way. The pump has to be strong enough to move the water fast through the system. It’s crucial to ensure you have plenty of ice for your needs!

Condenser

It’s responsible for turning the refrigerant gas into a liquid so you can use it to freeze the water in ice tubes.

Do you know how your car gets hot while driving, and you must turn on the air conditioner to cool it down? Your car’s AC system condenser works like a tube ice machine. It turns the hot refrigerant gas into a liquid by blowing air.

The condenser is usually outside and surrounded by metal fins in the tube ice maker. These fins help dissipate the heat. They also keep the refrigerant cool to continue freezing the water.

How Does a Tube Ice Machine Work?

The process of how tube ice machines work is simple. But requires precision and the best temperature to get the ice tubes right.

1. Pumping Water into the Evaporator

The first step in making ice tubes is to pump water into the evaporator. The evaporator is a long, hollow tube made of metal or plastic.

The water flows through the tube and distributes along the walls. Thanks to the built-in water distribution system. The water flows over the surface of the evaporator, and as it does, it starts to freeze.

But here’s the key: the water doesn’t freeze all at once. Instead, it forms a thin layer of ice on the surface of the evaporator. This is important because it creates a barrier between the rest of the water and the refrigerant.

2. The Refrigerant Cools the Evaporator

Here, the water has formed a thin layer of ice on the surface of the evaporator. Now it’s time for the refrigerant to do its thing. The refrigerant is a chemical that absorbs heat from the water, causing it to freeze. It’s pumped through a series of tubes surrounding the evaporator. These tubes cool the metal or plastic and cause the thin layer of ice to thicken.

You can use a thermostat to control the refrigerant’s temperature. This ensures that the ice tube formation happens at the right speed. This is important because the ice tubes won’t form well if the refrigerant is too cold or warm.

3. Ice Forms on the Evaporator

The refrigerant passes through the tubes surrounding the evaporator. The ice layer on the surface of the evaporator continues to thicken. In the end, it becomes thick enough that the ice forms a tube shape. Once the ice tubes reach the desired length, you can harvest them.

4. Harvesting and Storage of Ice

Here, you stop the refrigerant flow to harvest the ice tubes. You also need to heat the evaporator. This causes the ice tubes to loosen from the surface of the evaporator and slide down into a storage bin. From there, you can package, sell, or use it in various applications. Such applications may include keeping drinks cold or preserving food.

And that’s it! The process starts all over again by pumping fresh water into the evaporator. The cycle continues until you have enough ice tubes to meet your needs.

Advantages and Disadvantages of Tube Ice Makers

If you’re thinking about getting a tube ice maker, it’s important to consider both the pros and cons.

Benefits of Using a Tube Ice Machine

Here are some advantages of using tube ice machines:

- Quick Ice Production: Tube ice machines can produce ice fast. Furthermore, some models produce up to several tons daily. This is great for businesses that need a lot of ice on hand, like restaurants, bars, and hotels.

- Consistent Ice Size: With these machines, you can get ice in consistent sizes and shapes. This is especially crucial for businesses that need ice for specific applications. Businesses like cocktail bars need uniform ice cubes for drinks.

- Space Saving: Tube ice makers are generally more compact than other ice machines. This makes them an excellent choice for businesses that have a limited amount of space to spare.

- Energy Efficient: Many tube ice machines are energy-efficient. They use less electricity and water than other ice machines. This can help businesses save money on their utility bills.

- Low Maintenance: Tube ice makers are generally low-maintenance. They come with simple designs that are easy to clean and service. This can save businesses time and money on maintenance costs.

Tube ice machines offer many benefits for businesses that need a reliable source of ice. Whether running a restaurant, a hotel, or a bar, a tube ice maker can help you produce high-quality ice faster.

Drawbacks of Using a Tube Ice Machine

So, while tube ice machines are great for producing ice, they have a few disadvantages to remember. Here are some of the main ones:

- High Initial Cost: Tube ice machines can be pretty expensive. This is especially true if you need a larger machine to produce a lot of ice.

- Maintenance Requirements: These machines need regular maintenance to run like any machinery. This can include cleaning the evaporator, replacing parts, and checking refrigerant levels.

- Energy Usage: Tube ice machines may need a lot of energy. This, in turn, means that some of them generate higher electricity bills. This is especially true if you run a large machine for extended periods.

- Water Usage: Producing ice requires a lot of water, and tube ice machines are no exception. This means you’ll need a reliable source of clean water to keep your machine running.

- Size Limitations: Depending on your machine size, you may need more ice than you can produce at once. This can be a drawback if you must have large quantities of ice.

While a tube ice maker is great, knowing its limitations and drawbacks is important.

Tube Ice Machine Vs. Other Types of Ice Machines

If you’re looking for an ice machine, you might have heard about tube ice machines and other types. The most common are cube ice machines, flake ice machines, and tube ice machines. Here’s a breakdown of the differences and some features of a tube ice machine:

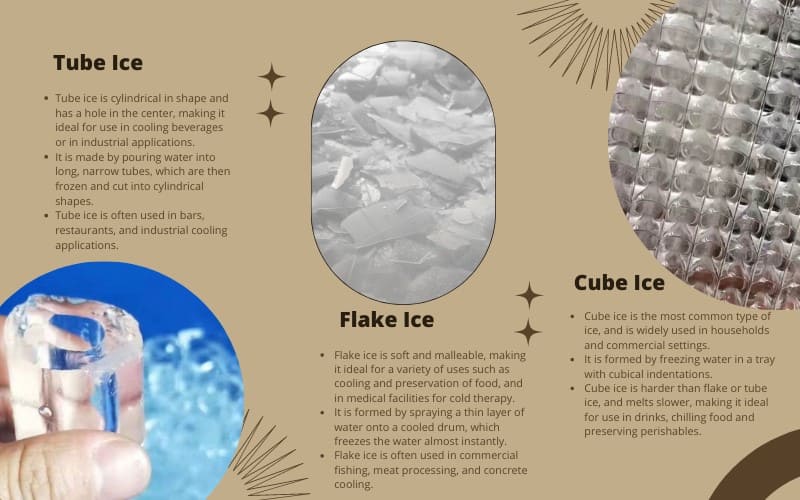

Ice Shape

Tube ice machines produce ice in the form of long, cylindrical tubes. These tubes are hollow and have a hole in the center. This makes them ideal for use in beverages or other applications where the ice needs to melt fast.

Other ice machines, such as flake or cube ice machines, produce ice in different shapes and sizes. Flake ice machines produce small, irregular-shaped flakes of ice. Flake ice is often used in seafood displays. Cube ice machines produce solid, square-shaped ice cubes often used in drinks.

Freezing Method

Another difference between tube ice machines and others is how they freeze the water. Tube ice machines use “falling film” to freeze the water. They pour a thin layer of water onto a vertical tube cooled by refrigerant.

As the water flows down the tube, it freezes into a cylindrical shape. Other ice machines use different methods to freeze the water. Such methods may include spraying it onto a cold surface or using a metal mold to shape the ice.

Quality of Ice

For one, tube ice is usually denser and longer-lasting than other types of ice. This is because it’s frozen in layers rather than all at once, like with an ice cube. Tube ice also tends to be clearer and more appealing. This makes it great for high-end cocktails and other drinks.

Energy Efficiency

Tube ice machines are often more energy-efficient than other ice machines. This is because they use a unique freezing process to produce more ice with less energy. A portable ice maker works to give you ice at your convenience. But, these ice makers are not as energy efficient as tube ice makers.

Cost

One advantage of tube ice machines is that they produce ice at a low cost and are efficient. They can also have much ice, making them ideal for commercial settings. Additionally, because tube ice is hollow, it melts fast, so it doesn’t dilute the drinks it uses.

Choosing between a tube ice machine and other types depends on your needs. If you need ice that melts well and doesn’t dilute drinks, a tube ice machine might be the way to go. But if you need ice in a different shape or size, consider a different type of ice machine. This is also true if you want a different freezing process.

Considerations When Choosing a Tube Ice Machine

Selecting the right tube ice machine can affect how well your business runs. There are a few things you’ll want to consider when making your choice:

Capacity and Size

Capacity refers to the amount of ice the machine can produce in a certain amount of time. For example, if you’re running a restaurant, you’ll need a higher capacity to meet the demand. But a smaller capacity might be enough if you’re using the machine for personal use at home.

Size is important because you must ensure the machine fits in your space. Tube ice machines come in different sizes. You’ll want to measure your space before purchasing. You want to avoid ending up with a machine that’s too big or too small for your needs.

Energy Efficiency

Now, why is energy efficiency important? Well, for starters, it can impact your energy bills. An energy-efficient machine will use less electricity, saving you more money. Plus, it’s better for the environment. A machine using less energy reduces the hot gas emissions produced.

When it comes to tube ice machines, a few things can affect their energy efficiency. One of the biggest factors is the compressor. This part of the machine compresses the refrigerant and pumps it through the system. A high-quality, energy-efficient compressor will use less electricity and produce less heat. This can help the machine run better.

Another thing to consider is the insulation. A well-insulated machine can maintain its temperature, which can help reduce energy usage. And of course, choosing the right size machine for your needs is important too. If you get a machine that’s too large, it will use more energy than necessary to produce ice.

Environmental Impact

First of all, the production of ice machines can hurt the environment. This is especially true if they are not made with sustainable materials or processes. This means looking for machines designed with the environment in mind is essential.

Another thing to consider is the amount of energy that the machine uses. A machine using a lot of energy can contribute to carbon emissions and hurt the environment. Looking for energy-efficient machines that use less energy is a good idea. In turn, they are better for the environment.

You’ll also want to consider the type of refrigerant used in the machine. Some refrigerants are harmful to the environment, while others are safer. So, choosing a machine that uses a safe refrigerant for the environment is essential.

Finally, you should consider the amount of water the machine uses. Some machines use a lot of water, which can be wasteful and contribute to water scarcity. Look for machines designed to conserve water and use it well.

Ease of Maintenance

What do we mean by ease of maintenance? Well, there are a few things to look out for. For one, choosing a machine that is easy to clean is important. This means that all the parts should be accessible. There should be no hard-to-reach areas that could collect dirt or bacteria. A machine with a built-in cleaning system can also help keep it clean and hygienic.

Another thing to consider is the availability of replacement parts. When something goes wrong with your ice machine, you want to be able to get it fixed as fast as possible. So, choosing a machine with available replaceable parts is important.

Finally, it’s important to choose a machine that comes with good customer support. If you have some questions or issues with your machine, you can contact someone who can help.

Price and Maintenance Costs

First, let’s talk about price. Tube ice machines can vary in price depending on their capacity, features, and brand. Generally, larger machines with more features will cost more than smaller, simpler machines.

While it is tempting to consider the cheapest option, it’s crucial to look at the long-term costs. A cheaper machine may cost you more in repairs and maintenance.

This brings us to the second consideration, maintenance costs. Choosing a tube ice machine that is easy to maintain and won’t need frequent repairs is important. The last thing you want is to use a lot of money on a machine that requires a lot of upkeep.

Look for machines that are easy to clean and have components that are easy to access for repairs. You’ll also want to consider the cost of replacement parts. Additionally, consider the availability of service technicians in your area.

Tips for Maintaining a Tube Ice Machine

If you’re considering buying a tube ice machine, remember it needs regular maintenance. This helps the machine to keep it functioning at its best. Here are some tips for maintaining your tube ice machine:

- Regular cleaning: Make sure to clean your tube ice machine. This means wiping down the exterior and interior of the machine. It also means cleaning the evaporator and other components.

- Check the water quality: The water you use in your tube ice machine can impact performance. Use clean, filtered water to reduce the risk of mineral buildup or other impurities.

- Check the condenser coil: The condenser coil is a vital machine part. This part needs regular cleaning. Dust and debris can accumulate on the coil, reducing its efficiency. Use a soft brush to clean the coil, and ensure it’s free from any blockage.

- Check the refrigerant levels: Low refrigerant levels can cause inefficiency. It also produces sub-par ice. It’s essential to check the refrigerant levels and, if needed, add more refrigerant.

- Inspect the water distribution system: A clean water distribution system produces high-quality ice. Inspect the system for any clogs or debris affecting its performance.

- Keep it well-ventilated: To prevent overheating, it must be in a well-ventilated area. Ensure there’s plenty of space around the machine for air to circulate.

- Check for leaks: Inspect your tube ice machine for any signs of leaks. Leaks can lead to a loss of refrigerant, which can cause the machine to stop working well.

- Schedule regular maintenance: It’s a good idea to schedule maintenance for your machine. This will help ensure that all components are working as they should. Also, you can make any necessary repairs or adjustments before they become bigger.

Following these tips can help ensure your tube ice machine operates at its best. You will also ensure that it continues producing high-quality ice for years.

Conclusion

So, there you have it! A beginner’s guide to tube ice machines and how they work. We hope this comprehensive article has given you a clear understanding of how you make tube ice. And the various types of tube ice machines available in the market.

Investing in a tube ice machine can be a wise decision whether you’re a business owner or a homeowner. It’s a convenient and cost-effective way to have a steady supply of ice. It removes the hassle of buying bags of ice from the store.

So, what are you waiting for? Go ahead and explore your options. Don’t hesitate to contact an ice machine professional if you have any questions. Cheers to never running out of ice again!